Same-day despatch on orders placed before 4pm*

Free delivery on orders over £300

Got a question? Speak to our industry experts on 01473 461800

Got a question? Speak to our industry experts on 01473 461800

Kerry Ingredients in Tenbury Wells is a Beverage and Yog Fruit site. With 300 employees operating a 7000 m2 production facility, this site supplies multiple high-end customers.

-

Background

As Production Systems Lead, Alex MacDonald’s responsibilities include implementing a site-wide Manufacturing Standard. This has a direct impact on production, as well as managing site and customer standards and expectations.

Alex was looking to increase the cleaning standard and organisation of the site and turned to Klipspringer for advice and assistance. -

The solution

Following comprehensive communication and detailed site surveys to establish the requirements of each area, Klipspringer designed and manufactured more than 50 bespoke shadow boards for the entire facility. Breaking the role-out into phases made the project and installation more manageable for the Kerry team.

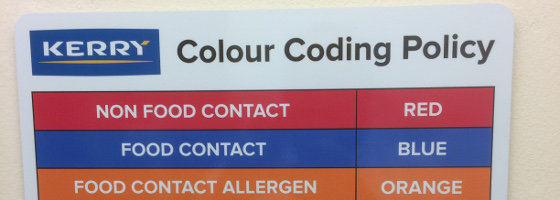

Klipspringer’s method of UV-cured direct print on robust aluminium composite material (ACM), heat-sealed with anti-scuff laminate gave Alex and his team the confidence their shadow boards were of the most robust and hygienic design, fit for the rigours of the food industry.

“Klipspringer offered us a management solution which allowed us to standardise aspects of our business across site. We started with implementing cleaning tool shadow boards in one 'pilot' area, but then swiftly cascaded this into other areas due to the success and support of the boards. We now use Shadow Boards for PPE, Cleaning, Tools & QC testing.”

“The Klipspringer team dealt with our requirements quickly, even when time was limited before major audits/visits. Klipspringer have a keen eye for detail – this allowed us to trust that the items we were ordering were of a high standard and matched our current site standards. Site visits and high communication allows a great team work feeling which allowed us to trust decisions and ideas made by the Klipspringer team.”Alex MacDonald, Kerry Ingredients -

Top tips and conclusion

Alex MacDonald has one particular top tip for any person or site considering shadow boards: “Review process flows in production areas and think of where in these areas you could improve by using shadow boards”.

Concluding, Alex said “it has been good and we worked well together” – the importance of working with a partner you can trust to give you the best advice and solutions cannot be overrated!