Same-day despatch on orders placed before 4pm*

Free delivery on orders over £300

Got a question? Speak to our industry experts on 01473 461800

Got a question? Speak to our industry experts on 01473 461800

'Industry 4.0' - and its impact on Food Production

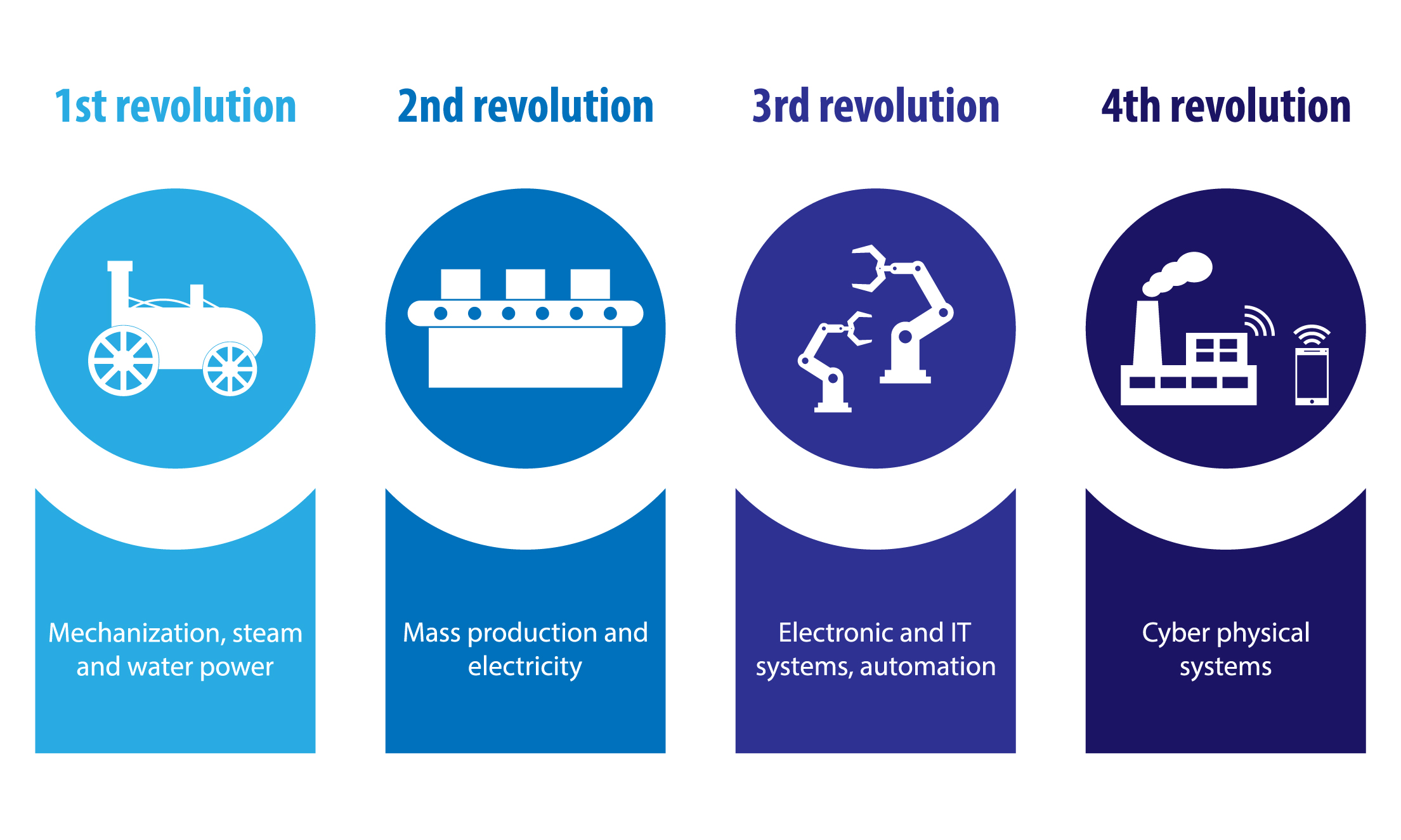

Manufacturing processes could be undergoing a period of great change, with interconnective automation being a readily available technology. Industry 4.0, also known as 4th industrial revolution, is utilising cyber-physical systems (CPS), the internet of things (IoT) and data analytics to revolutionise the market. The German-crafted technology will be changing the way we look at manufacturing processes of the future. Based on the fundamentals of interconnectivity, technological assistance, transparency of information and decentralised decision making, the intent of Industry 4.0 is to optimise all stages of production efficiency. It is undoubtable that as we begin to see a shift in manufacturing towards the 4.0 umbrella, food and beverage production processes will change.

Intelligent networking along your value chain

Networking between machines, work pieces and systems will create

an integration of processes between all of your factories. Industry 4.0 makes

it possible to interconnect all factories within a geographical location. The ability of peer-to-peer wireless connections allows data

collection to be distributed immediately to the right people. The system also can

become self-sufficient, not only allowing managers to increase efficiency, by

utilising the Enterprise Resource Planning (ERP), but also, through its

Enterprise Asset Management (EAM), it can forecast potential disruptions.

Finally, the Manufacturing Execution System (MES) quickly analyses the data,

distributing it, to aid ongoing development.

Quick access to diligently compiled data on an instantaneous basis, allows food manufacturers to consistently instil improvement and compliance. It has potential to allow managers to have better control over their practice and optimise their results – meeting targets. In fact, in a Forbes report, it was stated that 35% of companies that have adopted 4.0 are expecting a 20% revenue gain over the next five years. Increased reliability and the ability for a continuous, uninterrupted, production line could lead to a more lucrative market.

"35% of companies that have adopted 4.0 are expecting a 20% revenue gain over the next five years."

Forbes: The Fourth Industrial Revolution is here—are you ready?

Foreseeable Challenges

Food manufacturers will look at the opportunities offered by Industry 4.0 and want to aim towards making the transition. However, in practice this can be a very challenging ordeal. The time and monetary costs of transitioning to the new updated system is daunting. For some manufacturers, digitising all off their processes is an incredibly difficult and intellectually straining process. Then there are worries that are fuelled by unforeseen security and reliability issues. This, coupled with the redundancy that will come in replacing some departments within the work force, is resulting in some reluctancy (thus far) to welcome the impressive technology with open arms.

The Future of Food Production

Whilst the benefits to food production are undeniable, Industry 4.0 has some way to go when it comes to convincing every manufacturer to make the change. If the technology is correctly utilised, the scope for reliable, interconnective and self-sufficient production can streamline a company’s manufacturing processes. However, as we indefinitely move towards a more automotive world, perhaps these impacts are going to be more long term.